At Lansco Manufacturing, we have provided customers with high-quality components and assemblies delivered on time at competitive prices for over 35 years. One of our core service offerings is precision machining, a subtractive manufacturing process that allows us to produce parts and products with a high degree of precision and accuracy. By utilizing state-of-the-art multi-axis CNC equipment and employing skilled personnel, we can manufacture pieces in any quantity quickly, accurately, and cost-effectively.

The Precision Machining Process

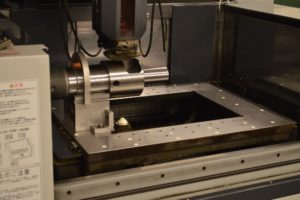

Precision machining is a manufacturing process used to turn raw materials into precise components. It utilizes computer numerical control (CNC) technology to automate the operation of the machining units, ensuring they achieve exact shapes and sizes.

The first step in the precision machining process is producing a computer-aided design (CAD) file for the desired component. This file is then run through a program (e.g., computer-aided manufacturing or CAM software) to generate instructions for the machining units. Once the units are set up, and the instructions are loaded to the units, the machine operator can initiate the program to start the precision machining operation.

Advantages of Precision Machining

Compared to other manufacturing methods, precision machining offers a number of advantages, such as:

- Higher accuracy: Since the precision machining process relies on computer-controlled technologies, it can produce more accurate physical representations of digital designs than are possible with manual machining processes.

- Better design repeatability: The use of computer-controlled technologies also ensures pieces are consistent from one part to the next and from batch to batch.

- Greater efficiency: Precision machining can produce parts and products at fast speeds with minimal human involvement.

- Lower waste production: The accuracy and precision of the precision machining process make it easy for manufacturers to optimize material usage and minimize material waste.

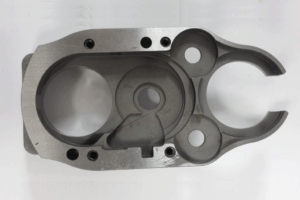

Precision Machining Applications

Precision machining finds application in a wide range of industries due to its numerous manufacturing advantages. For example:

- In the aerospace industry, it is used to produce aircraft components, such as land gears.

- In the automotive industry, it is used to produce automobile components, such as gearboxes and valves.

- In the electronics industry, it is used to produce components for electronic devices and systems, such as fixtures and housings.

In addition to being used for production operations, precision machining can be utilized for prototyping operations. The process’s high accuracy/precision and quick turnaround time make it well-suited for producing machined component prototypes.

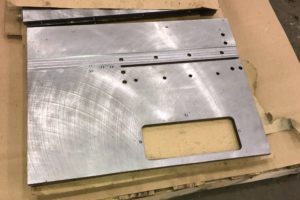

Types of Precision Machining Processes and Our Capabilities

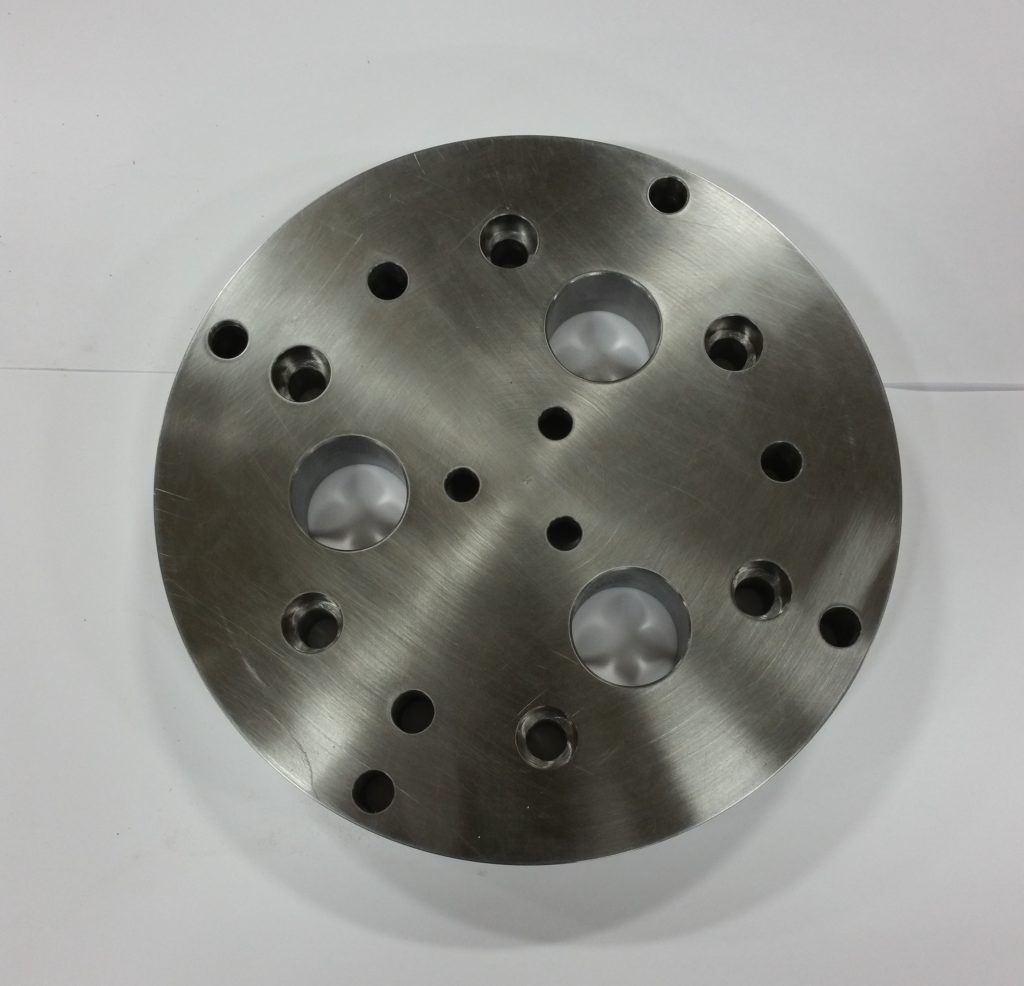

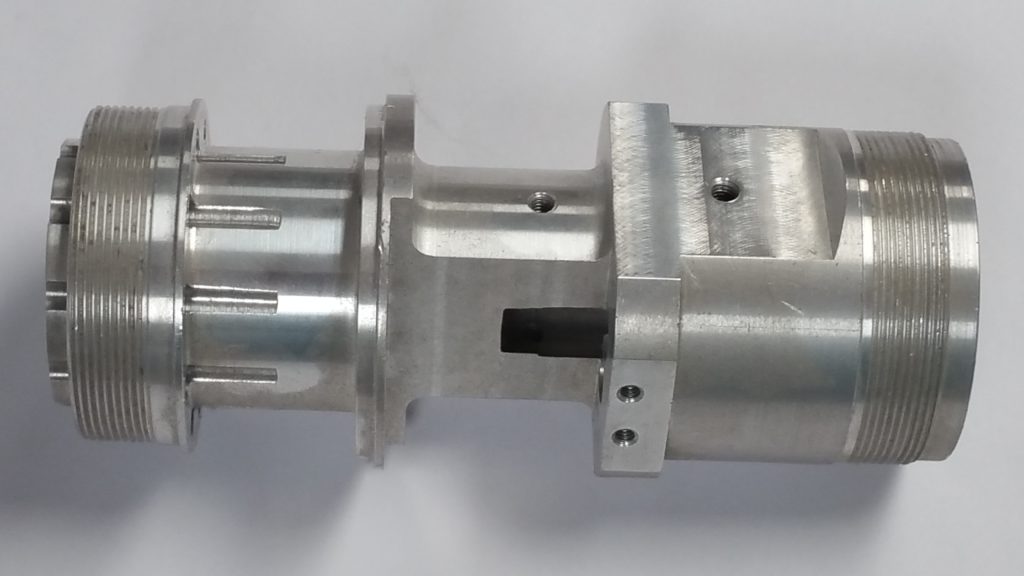

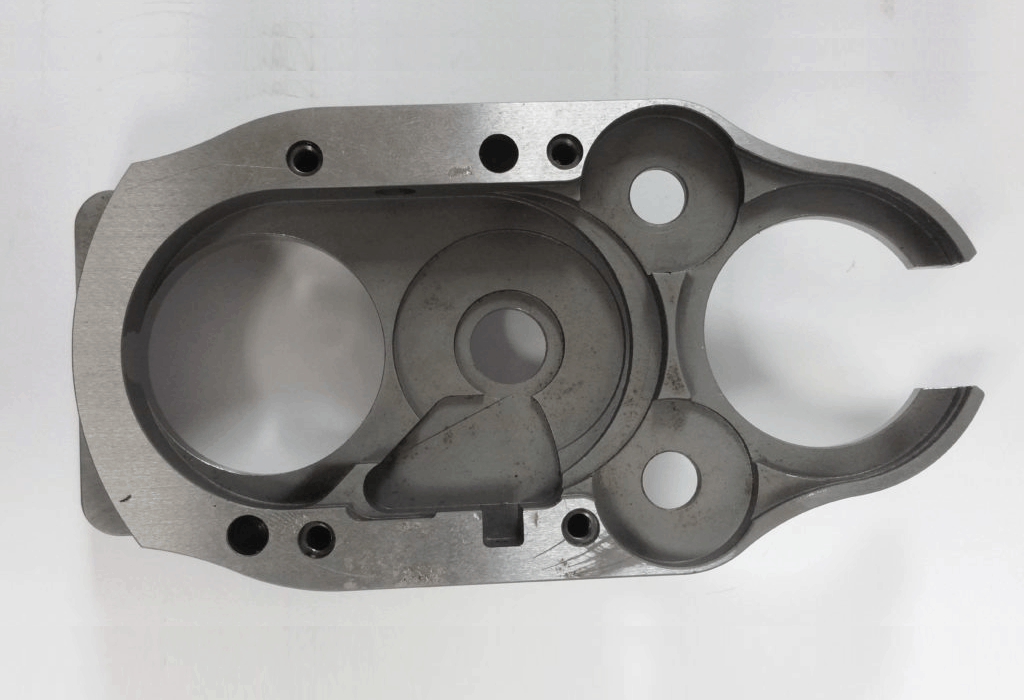

Precision machining is a broad term that encompasses many different processes. The machining experts at Lansco Manufacturing offer the following:

- CNC turning: This machining process uses computer-controlled cutting tools to remove material from a rotating workpiece. The cutting tools can move linearly or along angles and curves.

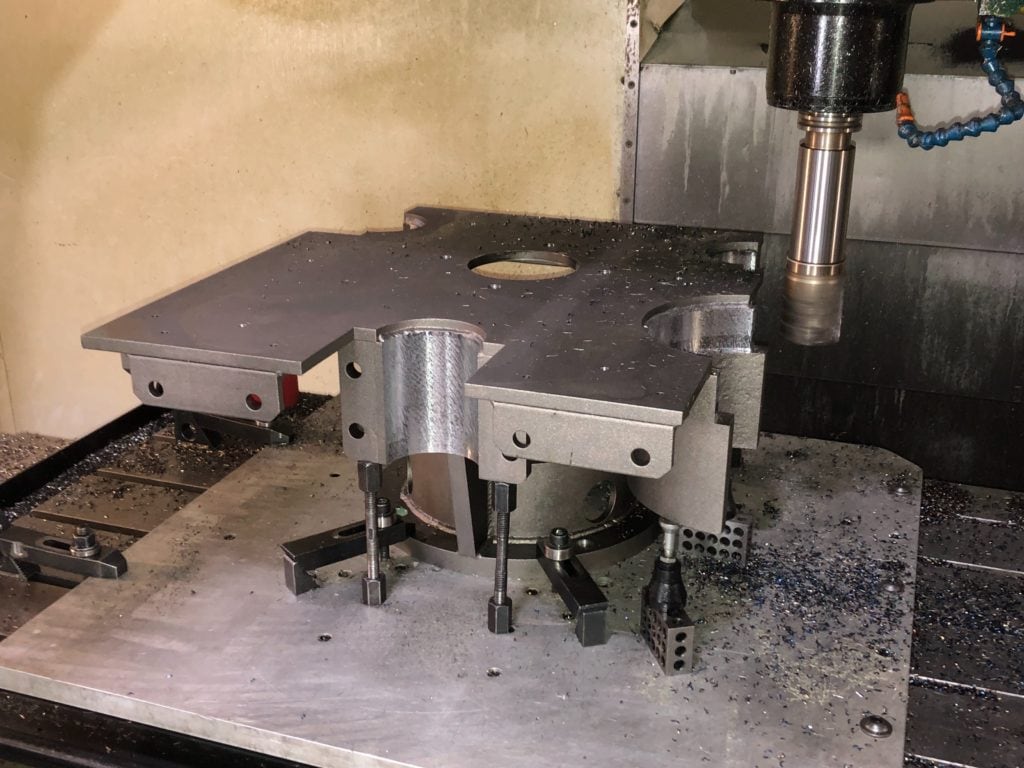

- CNC vertical machining: This machining process utilizes computer-controlled rotary cutting tools to remove material from a stationary workpiece. It is also known as milling.

- CNC horizontal milling and boring: This machining process employs a horizontal milling machine, which is ideal for projects that involve multiple cuts (e.g., parallel grooves) or hard materials.

- CNC Swiss turning: This machining process relies on the use of Swiss CNC machines (i.e., Swiss type lathes or Swiss automatic lathes) to provide small pieces accurately and quickly.

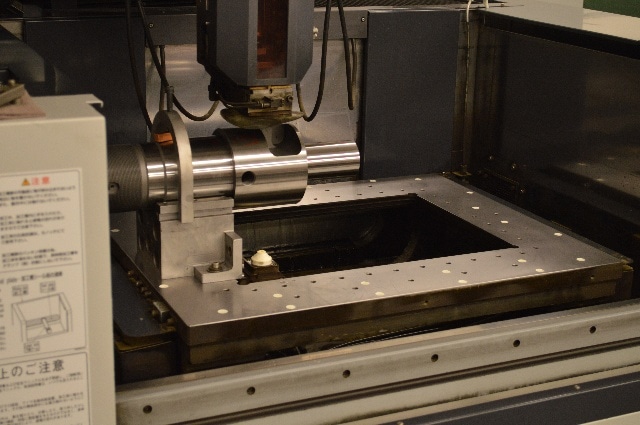

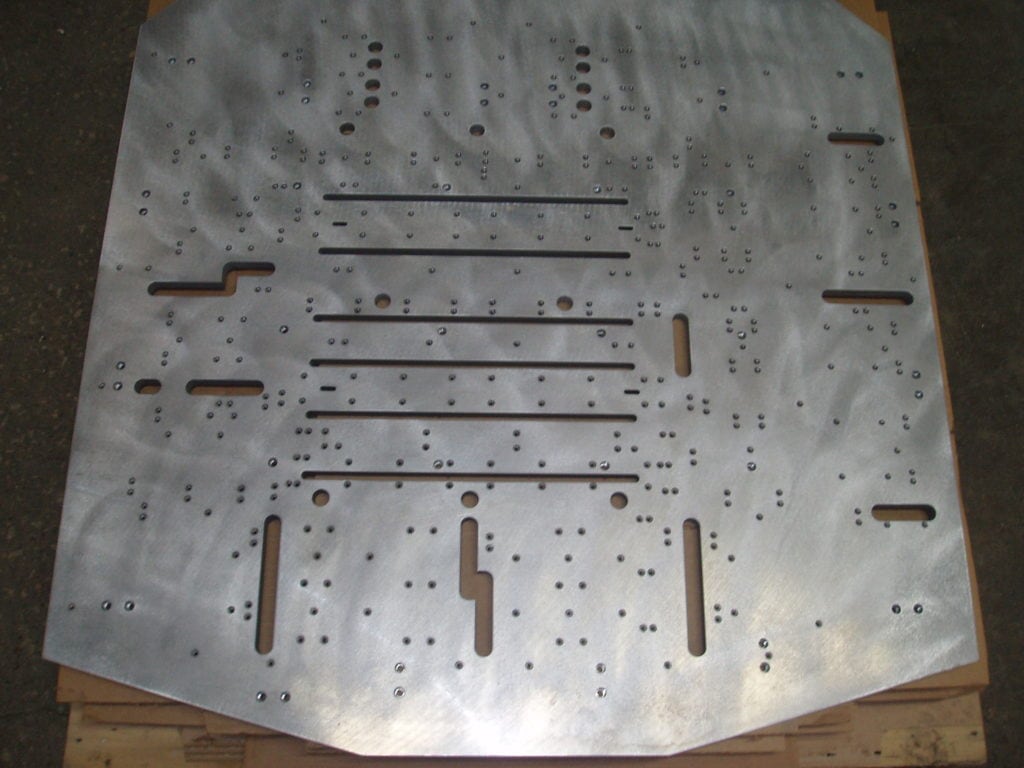

- CNC wire EDM: This process utilizes a precision electrode to accurately produce blind pockets or other features that are difficult or impossible to machine using other methods.

- CNC sinker EDM: This machining process is used to handle machining projects that are too difficult for other methods, such as those involving hardened conductive materials or complex designs.

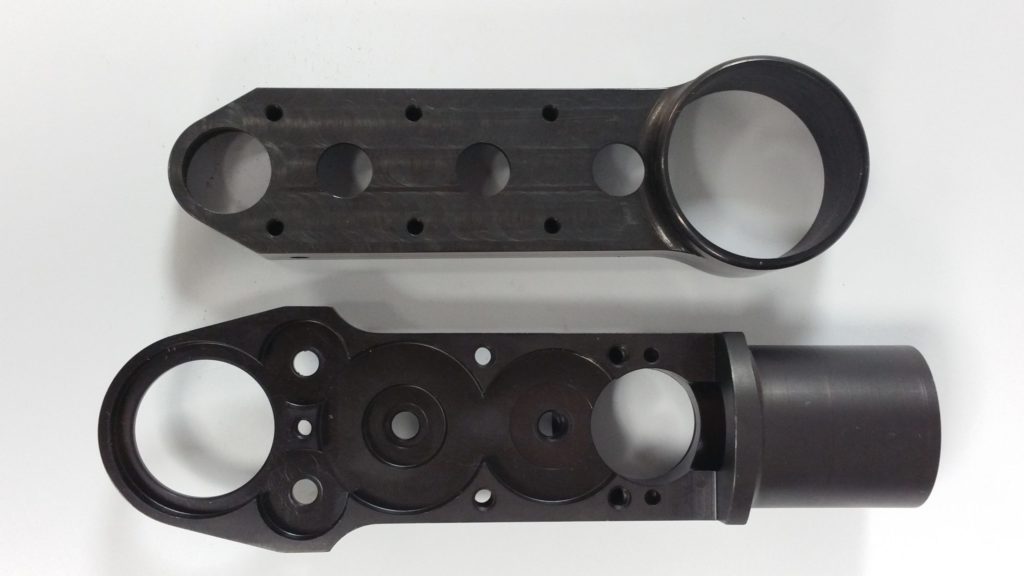

- Laser etching: This machining process employs laser technology to produce permanent markings on the surfaces of components.

- Grinding: This machining process utilizes abrasive media to achieve the desired tolerances and surface finishes for components.

- Tool Room Machining: This process utilizes skilled machinists and toolmakers to produce small quantities of parts quickly and cost effectively on two-axis ProtoTRAK controlled equipment.

Materials Worked

We can accommodate a variety of materials in our precision machining operations, such as:

- Carbon steel: a highly strong and durable metal

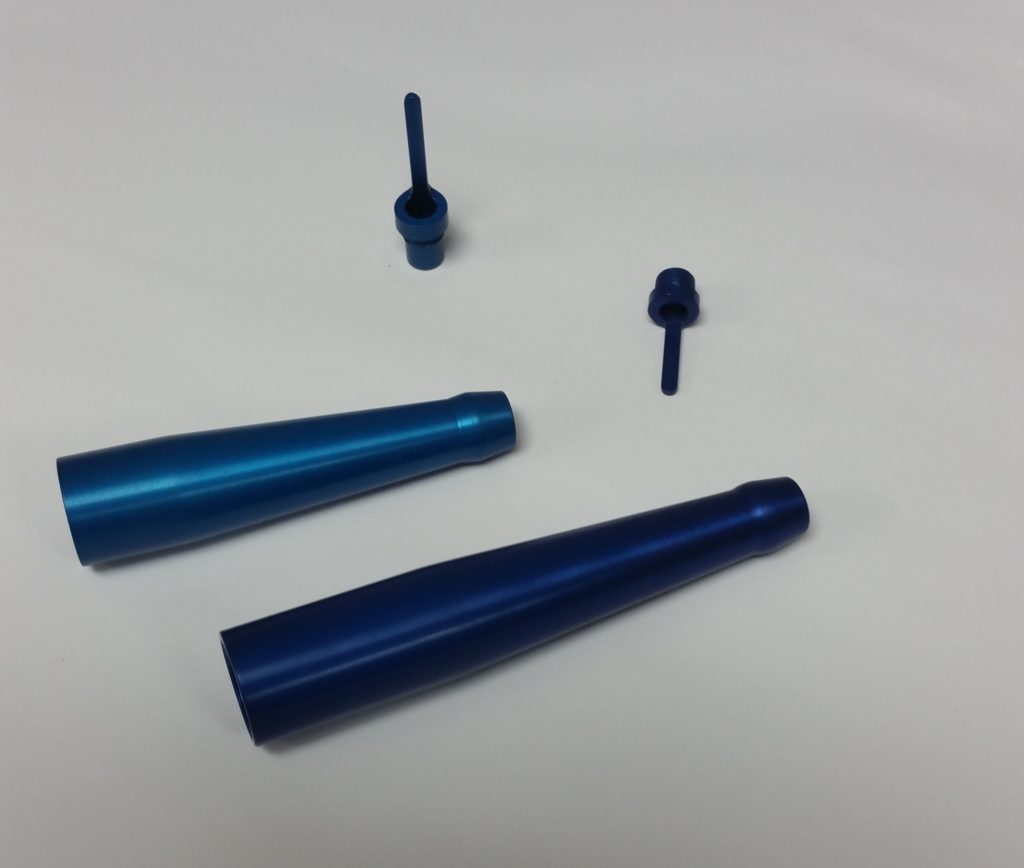

- Aluminum: a lightweight, corrosion resistant, and inexpensive metal

- Stainless steel: a strong and corrosion resistant metal

- Brass: an economical metal that machines easily

- Bronze: a metal that is excellent at conducting heat and electricity.

- Copper: a very electrically conductive metal

- Titanium: a metal with a good strength-to-weight ratio and high heat and corrosion resistance

- Plastic: an inexpensive and non-conductive material

Value-Added Services

In addition to our precision machining capabilities, we also offer a variety of value-added services to further support the needs of our customers. These include engineering support, tooling development, prototyping, and finishing (e.g., plating, anodizing, polishing, etc.). If needed, we can provide full turnkey machining solutions, which enable us to help customers at every stage of their project.

Contact Lansco Manufacturing for Your Precision Machining Needs Today

If you need precision machining services, Lansco Manufacturing is the ideal partner. By choosing us for your precision machining project, you benefit from our vast manufacturing experience, broad range of machining and value-added capabilities, quick turnaround times, and competitive prices. In addition to our precision machining services, we also offer precision stamping and custom sheet metal fabrication.

To learn more about our precision machining and other manufacturing capabilities, check out the table below or contact us today. To discuss your project requirements with one of our team members, request a quote.