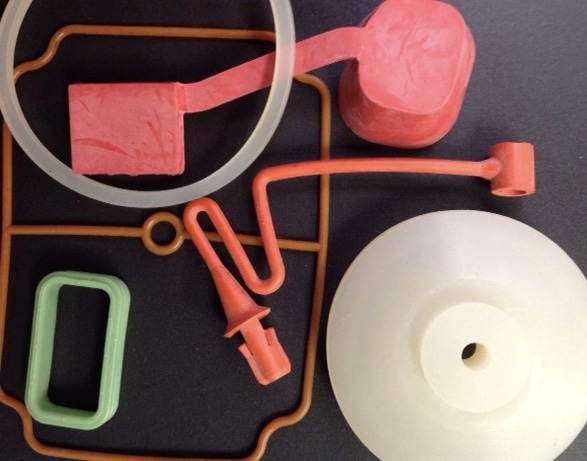

We provide a wide range of capabilities in the plastics industry including fabrication, machining, routing, stamping, die cutting, water jet cutting, welding, gluing, polishing and injection molding. We have access to most any plastic material and we can choose the best process for your application.

Plastics

Plastic Process

-

Notes

- Fabrication

-

Cutting

Forming

Welding

Gluing

Polishing

- Machining

-

CNC Turning

CNC Milling

CNC Routing

- Stamping

-

Cost Effective Tooling

Tool Steel Dies

- Die Cutting

-

Steel Rule Dies

CNC “Flash Cutting”

- Water Jet Cutting

-

5’ x 10’ Table

- Injection Molding

-

Short or Long Runs

Assemblies

Insert Molding

Screen Printing, Pad Printing, Labeling

- Types of parts

-

Gaskets

Seals

Covers

Tanks

Hoppers

Chutes

Sight GlassesDoors

Windows

Guards

Valves

Pump Components

Nozzles

Housings

- Materials (Partial List)

-

ABS

Acetal (Delrin)

Acrylic

Buna (Nitrile)

Durlon

EPDM

Ertalyte

G10

High Density Polyurethane (HDPE)

Micarta

Molded Rubber

Neoprene

Nylon

PEEK

Polycarbonate (Lexan)Polyethylene Terephthalate (PETE or PET)

Polyethylene (PE)

Polypropylene (PP)

Polystyrene (PS)

Polyurethane

Polyvinyl Chloride (PVC)

Rulon

Sheet Rubber

Silicone

Sponge Rubber

Teflon

Ultra High Molecular Weight (UHMW)

Vinyl

Viton